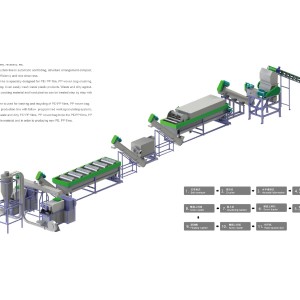

I-SJ Series iyisikulufu esisodwa esikhipha i-PP ne-HDPE izinto eziqinile nezikhanyiwe

Isistimu ye-pelletizing yesikulufu esisodwa

I-SJ Series iyisistimu yokugaywa kabusha kwe-screw extruder iwuhlelo olukhethekile noluthembekile olufanele ukugaywa kabusha nokuphindaphinda.Ihlanganisa umsebenzi we-plasticization kanye ne-pelletizing isinyathelo esisodwa.Okufana ne-PE echotshoziwe, amabhodlela e-PP nama-flakes ezigubhu namafilimu e-PE ahlanziwe futhi awakhanyiwe, kanye ne-ABS, i-PS, PP evela kuma-pallets, izihlalo, izinto zikagesi njll. Umthamo ungahluka kusuka ku-100-1100kg/h.

Izici zemishini:

1.Okopulasitiki abaqinile be-pelletizing

njenge-screw of the extruder yakhelwe ngokukhethekile amapulasitiki angcoliswe ngokuqhathaniswa anokuhlunga kabili.Ingakwazi ukwenza amapulasitiki aqinile we-PP, PE, ABS kanye ne-PC kanye namafilimu e-PP, amafilimu e-PE awashiwe.Umgqomo ungaba ukupholisa umoya noma ukupholisa amanzi.Futhi uhlobo lwe-pelletizing lungaba ukuchelela i-pelletizing, i-strand pelletizing kanye ne-pelletizing engaphansi kwamanzi.

2.Amafilimu e-PE PP ahlanjululwe futhi akhanyiwe.

Umswakama wezinto zokusetshenziswa kufanele ube ngaphakathi kuka-5-7%.Inesilo esikhulu esinesikulufu ukuze idlulisele ngokuzenzakalelayo okokusebenza ebhandeni, elizodlulisela impahla eluhlaza ku-extruder.

Umshini unezigaba ezimbili ungakwazi ukuhlunga ngempumelelo ukungcola futhi kulula Pelletize impahla eluhlaza ohlelweni ukuchelela pelletizing.

Isithombe sekesi:

Ngokwesicelo samakhasimende, singenza uhlelo lwe-pelletizing lube yi-strand pelletizing noma ngaphansi kwamanzi.

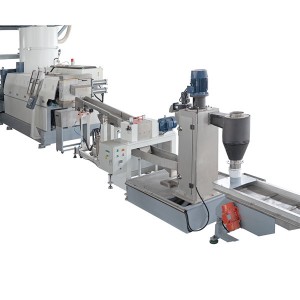

Isici:

Ngomklamo othuthukisiwe, okukhiphayo okuphezulu, ukwenziwa kwepulasitiki okuhle, ukusetshenziswa okuphansi, nokudluliswa kwegiya le-spline, inezinzuzo ezinjengomsindo ophansi, ukugijima okukudala, umthamo omuhle wokuthwala nempilo ende.

Imodeli ye-extruder yesiteji esisodwa

| Imodeli | I-SJ100 | I-SJ120 | I-SJ140 | I-SJ150 | I-SJ160 | I-SJ180 | SJ200 |

| Isikulufu ububanzi | 100 | 120 | 140 | 150 | 160 | 180 | 200 |

| L/D | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 | 18-42 |

| Isivinini sokujikeleza | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 |

| Okukhiphayo(kg/h) | 250-350 | 300-400 | 500-600 | 600-800 | 800-1000 | 900-1200 | 1000-1500 |

Imodeli ye-extruder yesiteji ezimbili

| Imodeli | SJ130/140 | SJ140/150 | SJ150/160 | SJ160/180 | SJ200/200 |

| Okukhiphayo(kg/h) | 500 | 600 | 800 | 1000 | 1000-1200 |

Umshini wepulasitiki ogaywe kabusha kanye ne-granulating uhlobo lwempahla esetshenziswa ukugaywa kabusha imfucumfucu yepulasitiki ibe yizinhlayiyana noma ama-pellets angasetshenziswa kabusha ekwenzeni imikhiqizo emisha yepulasitiki.Umshini ngokuvamile usebenza ngokuhlikihla noma ukugaya udoti wepulasitiki ube izingcezu ezincane, bese uyancibilikisa futhi uwukhiphe ngedayidi ukuze wakhe ama-pellets noma ama-granules.

Kunezinhlobo ezahlukene zemishini yokugaywa kabusha yepulasitiki kanye ne-granulating etholakalayo, okuhlanganisa isikulufu esisodwa kanye nezikhiphi eziphuma ngamawele.Eminye imishini ihlanganisa izici ezengeziwe ezifana nezikrini zokususa ukungcola emfucumfucwini yepulasitiki noma izinhlelo zokupholisa ukuze kuqinisekiswe ukuthi ama-pellets aqina ngendlela efanele.Umshini wokuwasha amabhodlela we-PET, umugqa wokugeza izikhwama we-PP

Imishini yokugaywa kabusha kwepulasitiki kanye ne-granulating ivamise ukusetshenziswa ezimbonini ezikhiqiza udoti omkhulu wepulasitiki, njengokupakisha, ezezimoto, nezokwakha.Ngokwenza kabusha imfucumfucu yepulasitiki, le mishini isiza ukunciphisa umthelela wemvelo wokulahlwa kwepulasitiki futhi ilondoloze izinsiza ngokusebenzisa kabusha izinto ebezingalahlwa.

Imishini yokugaywa kabusha kwebhethri ye-lithium iwuhlobo lwempahla esetshenziswa ukuphinda igaywe futhi ithole izinto ezibalulekile kumabhethri e-lithium-ion, avame ukusetshenziswa kumishini kagesi efana nama-smartphone, amalaptop, nezimoto zikagesi.Okokusebenza ngokuvamile kusebenza ngokwephula amabhethri ezingxenyeni zawo, njenge-cathode nezinto ze-anode, isixazululo se-electrolyte, namafoil ensimbi, bese ehlukanisa futhi ehlanza lezi zinto ukuze ziphinde zisetshenziswe.

Kunezinhlobo ezahlukene zemishini yokuvuselela ibhethri ye-lithium etholakalayo, okuhlanganisa izinqubo ze-pyrometallurgical, izinqubo ze-hydrometallurgical, nezinqubo zemishini.Izinqubo ze-Pyrometallurgical zibandakanya ukucutshungulwa kwezinga lokushisa eliphezulu kwamabhethri ukuze kubuyiselwe izinsimbi ezifana nethusi, i-nickel, ne-cobalt.Izinqubo ze-Hydrometallurgical zisebenzisa izixazululo zamakhemikhali ukuze zihlakaze izingxenye zebhethri futhi zibuyisele izinsimbi, kuyilapho izinqubo zemishini zihilela ukuhlakazeka nokugaya amabhethri ukuze ahlukanise izinto.

Imishini yokugaywa kabusha kwebhethri ye-lithium ibalulekile ekwehliseni umthelela wemvelo wokulahlwa kwebhethri nokulondoloza izinsiza ngokuthola izinsimbi ezibalulekile nezinto ezingasetshenziswa kabusha kumabhethri amasha noma kweminye imikhiqizo.

Ngaphezu kwezinzuzo zokongiwa kwemvelo nezinsiza, okokusebenza kabusha kwebhethri ye-lithium nakho kunezinzuzo zezomnotho.Ukuthola izinsimbi ezibalulekile nezinto ezisetshenziswayo kumabhethri asetshenzisiwe kunganciphisa izindleko zokukhiqiza amabhethri amasha, kuphinde kudale imizila yemali emisha yezinkampani ezibandakanyekayo enqubweni yokugaywa kabusha.

Ngaphezu kwalokho, ukwanda kwesidingo sezimoto zikagesi nezinye izinto zikagesi kuqhuba isidingo semboni esebenza kahle futhi esimeme yokugaywa kabusha kwamabhethri.Imishini yokugaywa kabusha kwebhethri ye-lithium ingasiza ukuhlangabezana nalesi sidingo ngokuhlinzeka ngendlela ethembekile nengabizi kakhulu yokuthola izinto ezibalulekile kumabhethri asetshenzisiwe.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugaywa kabusha kwebhethri ye-lithium kuseyimboni entsha uma kuqhathaniswa, futhi kunezinselelo okufanele uzinqobe mayelana nokuthuthukisa izinqubo zokugaywa kabusha ezisebenza kahle nezingabizi.Ukwengeza, ukuphatha kahle kanye nokulahlwa kwemfucuza yebhethri kubalulekile ukuze kugwenywe izingozi zemvelo nempilo.Ngakho-ke, kufanele kube nemithethonqubo efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukuphathwa kahle nokugaywa kabusha kwamabhethri e-lithium.