I-Hot Sale Isevisi Enhle Yomshini Wokuhlanza Umshini Wokuhlanza Kabusha

Isingeniso senqubo

Lo mzila wokukhiqiza uvuselela kabusha ifilimu yemfucuza yezolimo (ifilimu yezolimo/ifilimu ebamba ukushisa/ifilimu kagwayi, njll.).Njengamanje, ifilimu yemfucuza yezolimo icutshungulwa ezingxenyeni ezihlukahlukene zezwe ukuze isetshenziswe endaweni eyodwa futhi igaywe kabusha, futhi izinga lokuzenzekelayo kwemishini liyakhula.I-PULIER ibambe iqhaza ekwakhiweni kwemishini yokucubungula ifilimu yezolimo edoti kanye nemishini yokucubungula iminyaka eminingi, futhi imishini ivuselelwa njalo, ithuthukiswa futhi ithuthukisiwe futhi ixazulule izinkinga eziningi embonini ngobuchwepheshe bethu.Ngemuva kokuba ifilimu yemfucuza iqoqwe, icutshungulwa ngaphambili futhi isikwe noma inqunywe ukuze iguqule imiqulu emikhulu yefilimu yemfucuza ibe yizicucu ezincane bese iyifaka emshinini wokukhipha isihlabathi ukuze kusetshenziswe ukukhishwa kwesihlabathi.Okuqukethwe kwe-sediment okweqile kuzofinyeza impilo yesevisi ye-crusher futhi kuthinte umphumela wokuhlanza.Ngemuva kokususwa kwesihlabathi, ifilimu ingena ku-crusher ukuze iphathwe kahle.Amanzi anezelwa ukuchotshozwa, okungadlala indima yokuhlanza kokuqala.Iwasha i-friction ifakwe ngaphansi kwe-crusher, enganyakazisa i-sediment namanzi angcolile kumpahla ngaphandle.Ifilimu eyomisiwe ingena emshinini wokuwasha oqinile wokuhlanza ukungqubuzana.Lesi sigaba sigcwele amanzi okuhlanza ukungqubuzana.Inkampani yethu iklama ngokukhethekile lo mshini wokukhipha isihlabathi nokuhlanza ifilimu ye-mulch.I-sediment yokuhlanza ingaphezu kwama-99%.Ifilimu ehlanziwe ingena ku-washer entantayo bese imbiwa endaweni yokomisa ukuze iphelelwe amanzi.Okulandelayo kungaxhunywa kumugqa we-granulating ukwenza ama-granules.

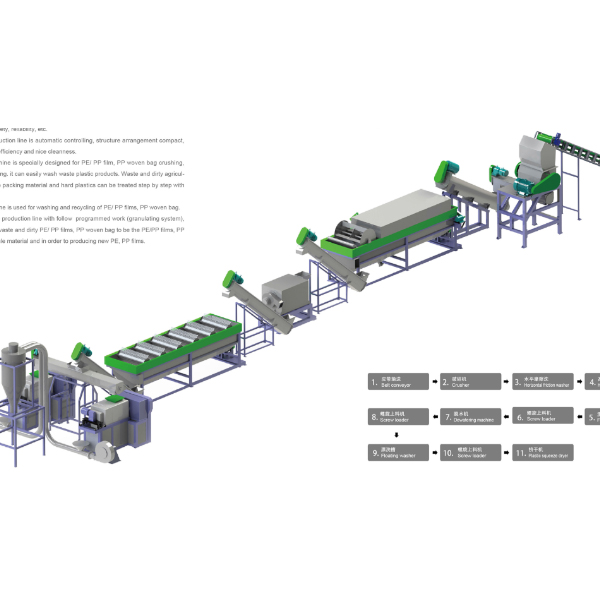

ukugeleza kokucubungula:

1. i-belt conveyor 2. crusher 3. screw loader 4. evundlile friction washer 5. high speed friction washer 6. screw loader 7. two tapper ithangi elintantayo

8. ovundlile friction washer 9. screw loader 10. ithangi lamanzi 11. horizontal spiral 12. screw loader 13. squeezer machine 14. silo

ividiyo sicela ubheke njengezixhumanisi ezingezansi:

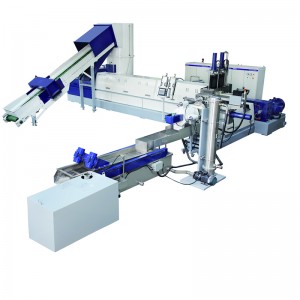

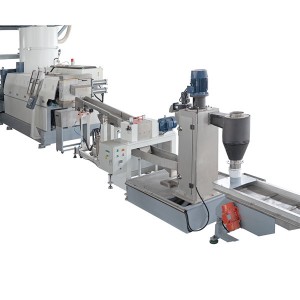

Umshini wepulasitiki ogaywe kabusha kanye ne-granulating uhlobo lwempahla esetshenziswa ukugaywa kabusha imfucumfucu yepulasitiki ibe yizinhlayiyana noma ama-pellets angasetshenziswa kabusha ekwenzeni imikhiqizo emisha yepulasitiki.Umshini ngokuvamile usebenza ngokuhlikihla noma ukugaya udoti wepulasitiki ube izingcezu ezincane, bese uyancibilikisa futhi uwukhiphe ngedayidi ukuze wakhe ama-pellets noma ama-granules.

Kunezinhlobo ezahlukene zemishini yokugaywa kabusha yepulasitiki kanye ne-granulating etholakalayo, okuhlanganisa isikulufu esisodwa kanye nezikhiphi eziphuma ngamawele.Eminye imishini ihlanganisa izici ezengeziwe ezifana nezikrini zokususa ukungcola emfucumfucwini yepulasitiki noma izinhlelo zokupholisa ukuze kuqinisekiswe ukuthi ama-pellets aqina ngendlela efanele.Umshini wokuwasha amabhodlela we-PET, umugqa wokugeza izikhwama we-PP

Imishini yokugaywa kabusha kwepulasitiki kanye ne-granulating ivamise ukusetshenziswa ezimbonini ezikhiqiza udoti omkhulu wepulasitiki, njengokupakisha, ezezimoto, nezokwakha.Ngokwenza kabusha imfucumfucu yepulasitiki, le mishini isiza ukunciphisa umthelela wemvelo wokulahlwa kwepulasitiki futhi ilondoloze izinsiza ngokusebenzisa kabusha izinto ebezingalahlwa.

Imishini yokugaywa kabusha kwebhethri ye-lithium iwuhlobo lwempahla esetshenziswa ukuphinda igaywe futhi ithole izinto ezibalulekile kumabhethri e-lithium-ion, avame ukusetshenziswa kumishini kagesi efana nama-smartphone, amalaptop, nezimoto zikagesi.Okokusebenza ngokuvamile kusebenza ngokwephula amabhethri ezingxenyeni zawo, njenge-cathode nezinto ze-anode, isixazululo se-electrolyte, namafoil ensimbi, bese ehlukanisa futhi ehlanza lezi zinto ukuze ziphinde zisetshenziswe.

Kunezinhlobo ezahlukene zemishini yokuvuselela ibhethri ye-lithium etholakalayo, okuhlanganisa izinqubo ze-pyrometallurgical, izinqubo ze-hydrometallurgical, nezinqubo zemishini.Izinqubo ze-Pyrometallurgical zibandakanya ukucutshungulwa kwezinga lokushisa eliphezulu kwamabhethri ukuze kubuyiselwe izinsimbi ezifana nethusi, i-nickel, ne-cobalt.Izinqubo ze-Hydrometallurgical zisebenzisa izixazululo zamakhemikhali ukuze zihlakaze izingxenye zebhethri futhi zibuyisele izinsimbi, kuyilapho izinqubo zemishini zihilela ukuhlakazeka nokugaya amabhethri ukuze ahlukanise izinto.

Imishini yokugaywa kabusha kwebhethri ye-lithium ibalulekile ekwehliseni umthelela wemvelo wokulahlwa kwebhethri nokulondoloza izinsiza ngokuthola izinsimbi ezibalulekile nezinto ezingasetshenziswa kabusha kumabhethri amasha noma kweminye imikhiqizo.

Ngaphezu kwezinzuzo zokongiwa kwemvelo nezinsiza, okokusebenza kabusha kwebhethri le-lithium nakho kunezinzuzo zezomnotho.Ukuthola izinsimbi ezibalulekile nezinto ezisetshenziswayo kumabhethri asetshenzisiwe kunganciphisa izindleko zokukhiqiza amabhethri amasha, kuphinde kudale imizila yemali emisha yezinkampani ezibandakanyekayo enqubweni yokugaywa kabusha.

Ngaphezu kwalokho, ukwanda kwesidingo sezimoto zikagesi nezinye izinto zikagesi kuqhuba isidingo semboni esebenza kahle futhi esimeme yokugaywa kabusha kwamabhethri.Imishini yokugaywa kabusha kwebhethri ye-lithium ingasiza ukuhlangabezana nalesi sidingo ngokuhlinzeka ngendlela ethembekile nengabizi kakhulu yokuthola izinto ezibalulekile kumabhethri asetshenzisiwe.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugaywa kabusha kwebhethri ye-lithium kuseyimboni entsha uma kuqhathaniswa, futhi kunezinselelo okufanele uzinqobe mayelana nokuthuthukisa izinqubo zokugaywa kabusha ezisebenza kahle nezingabizi.Ukwengeza, ukuphatha kahle kanye nokulahlwa kwemfucuza yebhethri kubalulekile ukuze kugwenywe izingozi zemvelo nempilo.Ngakho-ke, kufanele kube nemithethonqubo efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukuphathwa kahle nokugaywa kabusha kwamabhethri e-lithium.