Izigaba ezimbili zamapulasitiki Ifilimu nemicu kanye nezikhwama Umshini wokugcwalisa i-pelletizing

Ividiyo yomkhiqizo:

Icubungula Izithombe Ezibalulekile:

Ukucubungula Okubalulekile:

I-HDPE, i-LDPE, i-LLDPE, i-PP, efana namafilimu, izikhwama, ama-flakes, amarola wefilimu, ifilimu enwetshiwe, ifilimu eshwabene, ifilimu enezingqimba eziningi, izikhwama zesikibha ezisikiwe

I-PE enegwebu, i-EPS ne-XPS: amaroli, isikhwama, ishidi, isitsha sokudla, inetha lezithelo, ikhava

Indwangu: I-PP fiber, i-raffia, usilika, intambo, isikhwama esilukiwe, isikhwama se-jumbo

Izici:

Lolu hlelo oludidiyelwe lokuhlanganisa i-pelletizing luzuzisa izinto ezigaywe kabusha ngaphandle kokusikwa ngaphambili

I-compacting ifakwe ama-valves wokusika, asetshenziselwa ukulawula isivinini sokuphakela izinto ezibonakalayo

Isistimu ye-vacuum yokukhipha amanzi noma igesi ngezinga elikhulu

Isihlungi sesikrini se-hydraulic esihle kakhulu esinokucindezela okuzinzile kokungami, okungavuzi

Ukonga amandla ngokukhipha okuphezulu (0.28kwh/kg)

Inqubo yokusebenza evamile:

1.Ibhande lokudlulisa impahla libe yi-compactor ehlakazayo.

2.Isistimu yokulawula i-interlock phakathi kwebhande elidlulisa kanye nokusihlinza i-compactor iqinisekisa ukudla okulinganayo ngaphandle kwe-compactor encibilikile.

3.Phansi kwe-shredding compactor, kunebhodi elilodwa lokusika.ngamandla ayi-centrifugal, izinto ezigaywe kabusha zisikwa ngaphambili ngabasiki be-rotary abangaphakathi nabasiki abamile.

4.Ngemva kwalokho, into ingena kusikulufu sokususa umoya ukusuka ohlangothini lwekhompatha.

5.Ngokushisisa ngesikulufu, ipulasitiki iba impahla ye-semi-plastification.

6. Bese-ke, i-semi-plastic material isikwa ibe ama-pellets.

Ipharamitha Eyinhloko Yezobuchwepheshe:

| Imodeli | ML75 | I-ML85/SJ90 | I-ML100/SJ120 | I-ML130/SJ140 | I-ML160/SJ180 | I-ML180/SJ200 |

| Isikulufa ububanzi(mm) | 75 | Isigaba sokuqala 85Isigaba sesibili sama-90 | Isigaba sokuqala 100Isigaba sesibili se-120 | Isigaba sokuqala:130Isigaba sesibili:140 | Isigaba sokuqala:160Isigaba sesibili:180 | Isigaba sokuqala:180Isigaba sesibili:200 |

| L/D | Isigaba sokuqala: 26 kuya ku-37Isigaba sesibili:10 kuya ku-15 | |||||

| Okukhiphayo(kg/h) | 100-150 | 150-250 | 250- 350 | 450-550 | 600-800 | 1000 |

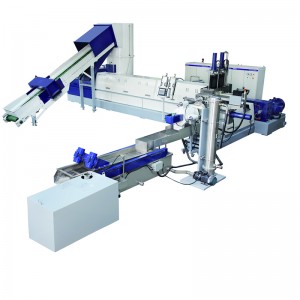

Izithombe zomshini:

I-scruder yesikulufu esisodwa

Isiteji esiphindwe kabili sokugaya kabusha i-extruder

Ulwazi oluvamile:

| Igama lemodeli | ML |

| okukhiphayo | Amapulangwe epulasitiki/ama-granules/ama-resins/i-plastic raw material |

| Izingxenye zomshini | I-belt conveyor, i-cutter compactor, i-extruder enkulu, iyunithi ye-pelletizing, isistimu yokupholisa, i-silo, ikhabethe |

| Izinto zokugaywa kabusha | Ifilimu ye-PP/PE/LDPE/HDPE, isikhwama, ifayibha |

| Ibanga lamandla | 100kg/h kuya ku-1200kg/h |

| Indlela yokudla | I-Conveyor, uhlelo lokushayela lwe-roll |

| Isikulufu ububanzi | 75mm ukuze 200mm |

| Isikulufu L/D | 26 ku33 |

| Isikulufa impahla eluhlaza | 38CrMoAl noma i-bimetallic |

| ukukhipha umoya | Ukukhishwa kwegesi kwemvelo, ukukhishwa kwe-vacuum degassing |

| Ukusika uhlobo | Indlela ye-pelletizing eqondile, donsa i-strip pelletizing |

| Uhlobo lokupholisa | Amanzi apholile, umoya opholile |

| i-voltage | Kwenziwe ngokwezifiso |

| Amadivayisi ozikhethela wona | Umtshina wensimbi, uhlelo lokupholisa amanzi, isisele sokudla, isistimu yokudlidliza |

| Isikhathi sokuthumela | Izinsuku ezingama-40 kuye kwezingama-60 |

| Isikhathi sewaranti | Izinyanga ezingu-13 |

| Izisekelo zobuchwepheshe | Isakhiwo somshini, isakhiwo sokufakwa, insizakalo kanjiniyela yaphesheya kwezilwandle |

| Isitifiketi | CE/ SGS/TUV/CO |

Kungani ukhethe thina?

I-A.PURUI inomkhiqizi ochwepheshe kusukela ngo-2006. sinomnyango wethu wokuklama lobuchwepheshe.I-extruder ngayinye iklanyelwe ngokuya ngesici sezinto ezibonakalayo.

B.Ukonga amandla ngokukhipha okuphezulu

Isikhathi sesiqinisekiso se-C.Quality yizinyanga eziyi-12 kusukela ngosuku Lomthethosivivinywa Wokuthwalwa Kwempahla.

D. Isikhathi sokudiliva: Izinsuku zokusebenza ezingama-40 kuya ezinsukwini ezingama-60

Iphakheji eceliwe ye-E.Ship

Ukufakwa kwe-F.Machine kuyatholakala.Kuthatha cishe izinsuku ezi-5 kuye kweziyi-7 ngokuqeda isikhathi esisodwa sokufaka.Onjiniyela abajutshiwe baphatha ukuqeqeshwa komsebenzisi womshini, ukusebenza komshini kanye nekhomishini.

Isingeniso Senkampani:

I-Chengdu PuRui Polymer Engineering Co. Ltd ingomunye wabakhiqizi abahamba phambili bemishini yokugaywa kabusha kwepulasitiki, i-extruder, i-plastic granulator kanye nezinto ezisizayo ezihlobene e-China.Izinzuzo eziyingqayizivele zesistimu yethu ye-plastic pelletizing idizayini yesikulufu, ukuphuma okuphezulu, ukukhipha umoya okuhle kanye nomphumela omuhle wokuhlunga.Ilayini yethu yokuwasha yepulasitiki efana ne-crusher enokumelana okubekezelelekayo kanye ne-cutter ebukhali, amayunithi okugeza, umshini wokuhlukanisa noma wokuhlunga, uhlelo lokumisa, kanye nesistimu yokupakisha kuyikhwalithi yomsindo.

Umshini wepulasitiki ogaywe kabusha kanye ne-granulating uhlobo lwempahla esetshenziswa ukugaywa kabusha imfucumfucu yepulasitiki ibe yizinhlayiyana noma ama-pellets angasetshenziswa kabusha ekwenzeni imikhiqizo emisha yepulasitiki.Umshini ngokuvamile usebenza ngokuhlikihla noma ukugaya udoti wepulasitiki ube izingcezu ezincane, bese uyancibilikisa futhi uwukhiphe ngedayidi ukuze wakhe ama-pellets noma ama-granules.

Kunezinhlobo ezahlukene zemishini yokugaywa kabusha yepulasitiki kanye ne-granulating etholakalayo, okuhlanganisa isikulufu esisodwa kanye nezikhiphi eziphuma ngamawele.Eminye imishini ihlanganisa izici ezengeziwe ezifana nezikrini zokususa ukungcola emfucumfucwini yepulasitiki noma izinhlelo zokupholisa ukuze kuqinisekiswe ukuthi ama-pellets aqina ngendlela efanele.Umshini wokuwasha amabhodlela we-PET, umugqa wokugeza izikhwama we-PP

Imishini yokugaywa kabusha kwepulasitiki kanye ne-granulating ivamise ukusetshenziswa ezimbonini ezikhiqiza udoti omkhulu wepulasitiki, njengokupakisha, ezezimoto, nezokwakha.Ngokwenza kabusha imfucumfucu yepulasitiki, le mishini isiza ukunciphisa umthelela wemvelo wokulahlwa kwepulasitiki futhi ilondoloze izinsiza ngokusebenzisa kabusha izinto ebezingalahlwa.

Imishini yokugaywa kabusha kwebhethri ye-lithium iwuhlobo lwempahla esetshenziswa ukuphinda igaywe futhi ithole izinto ezibalulekile kumabhethri e-lithium-ion, avame ukusetshenziswa kumishini kagesi efana nama-smartphone, amalaptop, nezimoto zikagesi.Okokusebenza ngokuvamile kusebenza ngokwephula amabhethri ezingxenyeni zawo, njenge-cathode nezinto ze-anode, isixazululo se-electrolyte, namafoil ensimbi, bese ehlukanisa futhi ehlanza lezi zinto ukuze ziphinde zisetshenziswe.

Kunezinhlobo ezahlukene zemishini yokuvuselela ibhethri ye-lithium etholakalayo, okuhlanganisa izinqubo ze-pyrometallurgical, izinqubo ze-hydrometallurgical, nezinqubo zemishini.Izinqubo ze-Pyrometallurgical zibandakanya ukucutshungulwa kwezinga lokushisa eliphezulu kwamabhethri ukuze kubuyiselwe izinsimbi ezifana nethusi, i-nickel, ne-cobalt.Izinqubo ze-Hydrometallurgical zisebenzisa izixazululo zamakhemikhali ukuze zihlakaze izingxenye zebhethri futhi zibuyisele izinsimbi, kuyilapho izinqubo zemishini zihilela ukuhlakazeka nokugaya amabhethri ukuze ahlukanise izinto.

Imishini yokugaywa kabusha kwebhethri ye-lithium ibalulekile ekwehliseni umthelela wemvelo wokulahlwa kwebhethri nokulondoloza izinsiza ngokuthola izinsimbi ezibalulekile nezinto ezingasetshenziswa kabusha kumabhethri amasha noma kweminye imikhiqizo.

Ngaphezu kwezinzuzo zokongiwa kwemvelo nezinsiza, okokusebenza kabusha kwebhethri ye-lithium nakho kunezinzuzo zezomnotho.Ukuthola izinsimbi ezibalulekile nezinto ezisetshenziswayo kumabhethri asetshenzisiwe kunganciphisa izindleko zokukhiqiza amabhethri amasha, kuphinde kudale imizila yemali emisha yezinkampani ezibandakanyekayo enqubweni yokugaywa kabusha.

Ngaphezu kwalokho, ukwanda kwesidingo sezimoto zikagesi nezinye izinto zikagesi kuqhuba isidingo semboni esebenza kahle futhi esimeme yokugaywa kabusha kwamabhethri.Imishini yokugaywa kabusha kwebhethri ye-lithium ingasiza ukuhlangabezana nalesi sidingo ngokuhlinzeka ngendlela ethembekile nengabizi kakhulu yokuthola izinto ezibalulekile kumabhethri asetshenzisiwe.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugaywa kabusha kwebhethri ye-lithium kuseyimboni entsha uma kuqhathaniswa, futhi kunezinselelo okufanele uzinqobe mayelana nokuthuthukisa izinqubo zokugaywa kabusha ezisebenza kahle nezingabizi.Ukwengeza, ukuphatha kahle kanye nokulahlwa kwemfucuza yebhethri kubalulekile ukuze kugwenywe izingozi zemvelo nempilo.Ngakho-ke, kufanele kube nemithethonqubo efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukuphathwa kahle nokugaywa kabusha kwamabhethri e-lithium.