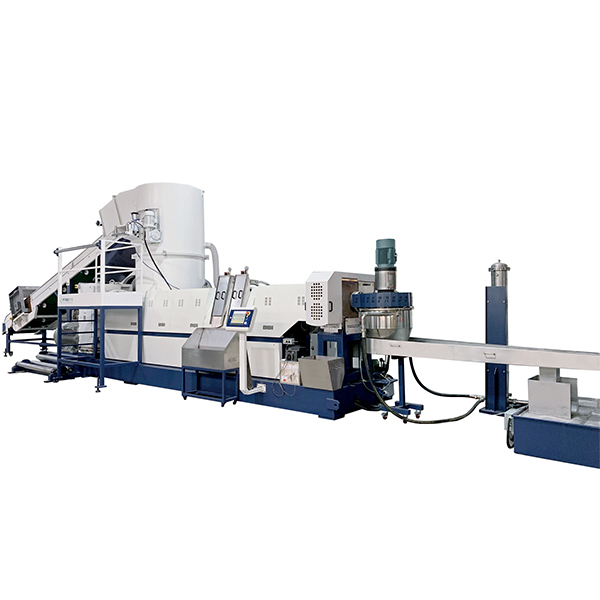

Umshini wokugcwalisa umshini wokugcwalisa ifilimu we-BOPP

Umshini wokugcwalisa ifilimu we-BOPP uhlanganisa imisebenzi yokuchoboza, ukuhlanganisa, ukwenza ipulasitiki kanye ne-granulation, futhi ilungele ukuvuselelwa kabusha kwepulasitiki kanye nezinqubo ze-granulation.I-BOPP ifilimu granulator iyisixazululo esinokwethenjelwa nesisebenzayo sokubuyisela kabusha kanye ne-pelletizing yefilimu yepulasitiki, i-raffia fiber, i-filament, isikhwama, isikhwama esilukiweyo kanye nezinto zegwebu.Umkhiqizo wokugcina okhiqizwe yi-Fangsheng BOPP ifilimu ye-granulator/pelletizer isesimweni sama-granules/granules, angafakwa ngokuqondile emgqeni wokukhiqiza wokuvuthela ifilimu, ukukhishwa kwepayipi kanye nomjovo wepulasitiki, njll.

Umshini uwuhlobo lomshini wokwenza kabusha ipulasitiki.Ingadlulisela i-matrial yemfucuza kuma-pellets awusizo ukuze kuqhutshekwe nokukhiqizwa.

Izici zomshini we-BOPP Film Granulating:

1. Umshini we-BOPP wefilimu ye-granulating unokuvumelana nezimo ezinhle, cishe zonke izinhlobo ze-granulation yepulasitiki evamile zingashintshwa.Isilinganiso sokusetshenziswa kwamandla komshini wokubuyisela kabusha ipulasitiki siphansi.Izinga lomkhiqizo ophumayo kanye nenzuzo ephelele yokuncintisana isobala.

2. Ekupheleni komgqomo wesikulufu, i-granulator egaywe kabusha efakwe ikholomu ephindwe kabili esheshayo yokushintsha isikrini se-hydraulic non-stop ingahlunga ngempumelelo ukungcola okukuncibilika kwepulasitiki.

3. Izinhlayiya ezintsha ngemva kokubumba igalelo noma umjovo zingasetshenziswa ukwenza imikhiqizo emisha yepulasitiki.Isibonelo, amafilimu epulasitiki, izikhwama zepulasitiki, amabhodlela epulasitiki, ama-pallets epulasitiki, amabhokisi epulasitiki, imiphongolo yepulasitiki, njll.

4. Isistimu yokusabalalisa amandla okuzenzakalelayo yamukelwa ukuze kuqinisekiswe ukusebenza okuvamile kwemoto.

Amafilimu e-BOPP Asebenzisa Kabusha Umshini Wokugaywa Kabusha Ipharamitha Yezobuchwepheshe:

Okuvamile:

| Imodeli | ML85 | I-ML100 | I-ML130 | I-ML160 | I-ML180 |

| Okukhiphayo(kg/h) | 120-180 | 180-300 | 400-500 | 600-800 | 800-1000 |

Okukhiphayo okuphezulu, ukusetshenziswa okuphansi:

| Imodeli | I-ML100B | I-ML130B | I-ML160B | I-ML180B |

| Okukhiphayo(kg/h) | 350-400 | 500-600 | 600-800 | 1000-1100 |

Amafilimu e-BOPP Asebenzisa Kabusha Umshini Wokugawula Inqubo Yokusebenza:

ifilimu ye-bopp→ibhande elihambisa ibhande→ikhompiyutha→isikulufa esisodwa esiyisikulufa →isishintshi sesikrini esisebenza ngaphansi kwamanzi →uhlelo lokupeteleza →ukuhanjiswa komoya →isitoreji sesisele

Imininingwane Yensiza Yezisetshenziswa Zefilimu ye-BOPP:

I-Water-ring Die-face cutting system

Izindlela zokusika i-water-ring die-face/Strand zivame ukusetshenziswa.Kusistimu yokusika i-water-ring die-face, izindwani zokusika ezijikelezayo zizolingana ngokuphelele futhi zisondele endaweni yobuso be-die-face ukuze kuqinisekiswe ukusika okusebenzayo.Isivinini sokujikeleza kwama-blades silungiswa ngokuzenzakalelayo ngohlelo lwemojula ngokuya ngengcindezi encibilikayo ebusweni bokufa.

ividiyo:

Noma yimuphi umbuzo, sicela usithinte ngokukhululekile.

Umshini wepulasitiki ogaywe kabusha kanye ne-granulating uhlobo lwempahla esetshenziswa ukugaywa kabusha imfucumfucu yepulasitiki ibe yizinhlayiyana noma ama-pellets angasetshenziswa kabusha ekwenzeni imikhiqizo emisha yepulasitiki.Umshini ngokuvamile usebenza ngokuhlikihla noma ukugaya udoti wepulasitiki ube izingcezu ezincane, bese uyancibilikisa futhi uwukhiphe ngedayidi ukuze wakhe ama-pellets noma ama-granules.

Kunezinhlobo ezahlukene zemishini yokugaywa kabusha yepulasitiki kanye ne-granulating etholakalayo, okuhlanganisa isikulufu esisodwa kanye nezikhiphi eziphuma ngamawele.Eminye imishini ihlanganisa izici ezengeziwe ezifana nezikrini zokususa ukungcola emfucumfucwini yepulasitiki noma izinhlelo zokupholisa ukuze kuqinisekiswe ukuthi ama-pellets aqina ngendlela efanele.Umshini wokuwasha amabhodlela we-PET, umugqa wokugeza izikhwama we-PP

Imishini yokugaywa kabusha kwepulasitiki kanye ne-granulating ivamise ukusetshenziswa ezimbonini ezikhiqiza udoti omkhulu wepulasitiki, njengokupakisha, ezezimoto, nezokwakha.Ngokwenza kabusha imfucumfucu yepulasitiki, le mishini isiza ukunciphisa umthelela wemvelo wokulahlwa kwepulasitiki futhi ilondoloze izinsiza ngokusebenzisa kabusha izinto ebezingalahlwa.

Imishini yokugaywa kabusha kwebhethri ye-lithium iwuhlobo lwempahla esetshenziswa ukuphinda igaywe futhi ithole izinto ezibalulekile kumabhethri e-lithium-ion, avame ukusetshenziswa kumishini kagesi efana nama-smartphone, amalaptop, nezimoto zikagesi.Okokusebenza ngokuvamile kusebenza ngokwephula amabhethri ezingxenyeni zawo, njenge-cathode nezinto ze-anode, isixazululo se-electrolyte, namafoil ensimbi, bese ehlukanisa futhi ehlanza lezi zinto ukuze ziphinde zisetshenziswe.

Kunezinhlobo ezahlukene zemishini yokuvuselela ibhethri ye-lithium etholakalayo, okuhlanganisa izinqubo ze-pyrometallurgical, izinqubo ze-hydrometallurgical, nezinqubo zemishini.Izinqubo ze-Pyrometallurgical zibandakanya ukucutshungulwa kwezinga lokushisa eliphezulu kwamabhethri ukuze kubuyiselwe izinsimbi ezifana nethusi, i-nickel, ne-cobalt.Izinqubo ze-Hydrometallurgical zisebenzisa izixazululo zamakhemikhali ukuze zihlakaze izingxenye zebhethri futhi zibuyisele izinsimbi, kuyilapho izinqubo zemishini zihilela ukuhlakazeka nokugaya amabhethri ukuze ahlukanise izinto.

Imishini yokugaywa kabusha kwebhethri ye-lithium ibalulekile ekwehliseni umthelela wemvelo wokulahlwa kwebhethri nokulondoloza izinsiza ngokuthola izinsimbi ezibalulekile nezinto ezingasetshenziswa kabusha kumabhethri amasha noma kweminye imikhiqizo.

Ngaphezu kwezinzuzo zokongiwa kwemvelo nezinsiza, okokusebenza kabusha kwebhethri ye-lithium nakho kunezinzuzo zezomnotho.Ukuthola izinsimbi ezibalulekile nezinto ezisetshenziswayo kumabhethri asetshenzisiwe kunganciphisa izindleko zokukhiqiza amabhethri amasha, kuphinde kudale imizila yemali emisha yezinkampani ezibandakanyekayo enqubweni yokugaywa kabusha.

Ngaphezu kwalokho, ukwanda kwesidingo sezimoto zikagesi nezinye izinto zikagesi kuqhuba isidingo semboni esebenza kahle futhi esimeme yokugaywa kabusha kwamabhethri.Imishini yokugaywa kabusha kwebhethri ye-lithium ingasiza ukuhlangabezana nalesi sidingo ngokuhlinzeka ngendlela ethembekile nengabizi kakhulu yokuthola izinto ezibalulekile kumabhethri asetshenzisiwe.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugaywa kabusha kwebhethri ye-lithium kuseyimboni entsha uma kuqhathaniswa, futhi kunezinselelo okufanele uzinqobe mayelana nokuthuthukisa izinqubo zokugaywa kabusha ezisebenza kahle nezingabizi.Ukwengeza, ukuphatha kahle kanye nokulahlwa kwemfucuza yebhethri kubalulekile ukuze kugwenywe izingozi zemvelo nempilo.Ngakho-ke, kufanele kube nemithethonqubo efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukuphathwa kahle nokugaywa kabusha kwamabhethri e-lithium.