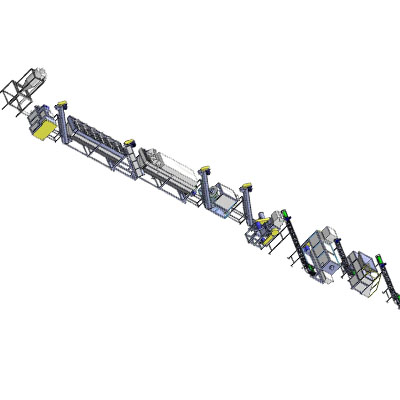

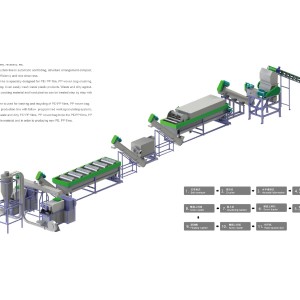

I-PP Jumbo Bag Crushing Washing Drying Pelletizing Recycling Machine

Imfucuza ye-PP yokwelukiweyo yomshini wokuwasha isikhwama esigaywe kabusha iqukethe: umshini wokuthungatha ibhande, i-crusher (i-grinder), iwasha ehambisana nesivinini esikhulu, iwasha elintantayo, umshini wokukhipha amanzi, umshini wokucindezela, nezinye izinto.imininingwane sicela ubheke le vidiyo.

imininingwane yokucubungula:

| NO | Inqubo | Umshini | Incazelo |

| 1 | Thumela isikhwama esilukiweyo emshinini we-crusher omanzi | I-Conveyor ene-Metal Detector(Ongakukhetha) | Ihlukanisa ukungcola okufana nezinsimbi esikhwameni esilukiweyo, Ithumela izinto emshinini we-crusher omanzi |

| 2 | Sika isikhwama esilukiwe se-pp sibe izingcezu ezincane | Umshini Wokuhlikihla Omanzi | I-crusher emanzi isika isikhwama esilukiwe se-PP sibe izingcezu ezincane cishe ngosayizi ongu-10-20mm bese sidlulela ocezwini olulandelayo lwesisetshenziswa. |

| 3 | Thumela isikhwama esilukiweyo emshinini wokuwasha ontantayo | I-Screw feeder | Faka isikhwama esilukiwe ku-Hot washer ukuze usihlanze |

| 4 | Isikhathi sokuqala esintantayo geza isikhwama esilukiwe | Ithangi Lokugeza Elintantayo | Njengoba isikhwama esilukiwe singena emshinini wokuwasha, isikhwama esilukiwe siyakhuhlana ngesivinini esikhulu sikhipha ukungcola okunzima ukukususa. |

| 5 | Ukuphakela izinsalela zezikhwama ezilukiweyo kumshini wokuwasha | I-Screw feeder | Faka isikhwama esilukiwe ku-High-speed Friction Washer ukuze usihlanze |

| 6 | Hlukanisa ukungcola esikhwameni esilukiwe sepulasitiki | Umshini Wokuwasha Onesivinini Esikhulu | Ngemva kokuchotshozwa kwezinto ezivela emlonyeni, ngesivinini esiphezulu ku-axis ye-blade flap bese ufutha amanzi emsebenzini ovamile womphumela omuhle wokuhlanza. |

| 7 | Okwesibili Ezintantayo geza isikhwama esilukiwe | Ithangi Lokugeza Elintantayo | Isetshenziselwa ukuhlanza izikhwama zepulasitiki ezilukiweyo, ukwenza ifilimu ihlanzeke. |

| 8 | Sula isikhwama esilukiwe sepulasitiki | Umshini Wokukhipha amanzi Ovundlile | Umshini wokukhipha amanzi usebenzisa amandla e-centrifugal ukuphotha umswakama wamanzi esikhwameni esilukiwe sepulasitiki. |

| 9 | Umoya oshisayo womisa isikhwama esilukiwe | Sumshini we-queezer | Sukukhama izintosusa umswakama ezintweni ezihlanzekile. |

| 10 | Gcina izingcezu ezomile zesikhwama esilukiwe | Isitoreji silo | Ithangi lokugcina lezingcezu ezihlanzekile, ezomile zesikhwama esilukiwe. |

| 11 | yenza isikhwama sepulasitiki esilukiwe sibe ama-granules(Uma uthanda) | I-Pelletizer / Extruder | Sinikeza kokubili ama-extruder-screw extruder nama-twin-screw extruder.Ngokusekelwe kuzimfuneko zakho, sinikeza kokubili isigaba esisodwa kanye nesigaba esiphindwe kabili sokusethwa kwe-pelletizing lapho ama-granules angakhiwa kusetshenziswa i-granulator noma ukusika indandatho yamanzi. |

Umshini wepulasitiki ogaywe kabusha kanye ne-granulating uhlobo lwempahla esetshenziswa ukugaywa kabusha imfucumfucu yepulasitiki ibe yizinhlayiyana noma ama-pellets angasetshenziswa kabusha ekwenzeni imikhiqizo emisha yepulasitiki.Umshini ngokuvamile usebenza ngokuhlikihla noma ukugaya udoti wepulasitiki ube izingcezu ezincane, bese uyancibilikisa futhi uwukhiphe ngedayidi ukuze wakhe ama-pellets noma ama-granules.

Kunezinhlobo ezahlukene zemishini yokugaywa kabusha yepulasitiki kanye ne-granulating etholakalayo, okuhlanganisa isikulufu esisodwa kanye nezikhiphi eziphuma ngamawele.Eminye imishini ihlanganisa izici ezengeziwe ezifana nezikrini zokususa ukungcola emfucumfucwini yepulasitiki noma izinhlelo zokupholisa ukuze kuqinisekiswe ukuthi ama-pellets aqina ngendlela efanele.Umshini wokuwasha amabhodlela we-PET, umugqa wokugeza izikhwama we-PP

Imishini yokugaywa kabusha kwepulasitiki kanye ne-granulating ivamise ukusetshenziswa ezimbonini ezikhiqiza udoti omkhulu wepulasitiki, njengokupakisha, ezezimoto, nezokwakha.Ngokwenza kabusha imfucumfucu yepulasitiki, le mishini isiza ukunciphisa umthelela wemvelo wokulahlwa kwepulasitiki futhi ilondoloze izinsiza ngokusebenzisa kabusha izinto ebezingalahlwa.

Imishini yokugaywa kabusha kwebhethri ye-lithium iwuhlobo lwempahla esetshenziswa ukuphinda igaywe futhi ithole izinto ezibalulekile kumabhethri e-lithium-ion, avame ukusetshenziswa kumishini kagesi efana nama-smartphone, amalaptop, nezimoto zikagesi.Okokusebenza ngokuvamile kusebenza ngokwephula amabhethri ezingxenyeni zawo, njenge-cathode nezinto ze-anode, isixazululo se-electrolyte, namafoil ensimbi, bese ehlukanisa futhi ehlanza lezi zinto ukuze ziphinde zisetshenziswe.

Kunezinhlobo ezahlukene zemishini yokuvuselela ibhethri ye-lithium etholakalayo, okuhlanganisa izinqubo ze-pyrometallurgical, izinqubo ze-hydrometallurgical, nezinqubo zemishini.Izinqubo ze-Pyrometallurgical zibandakanya ukucutshungulwa kwezinga lokushisa eliphezulu kwamabhethri ukuze kubuyiselwe izinsimbi ezifana nethusi, i-nickel, ne-cobalt.Izinqubo ze-Hydrometallurgical zisebenzisa izixazululo zamakhemikhali ukuze zihlakaze izingxenye zebhethri futhi zibuyisele izinsimbi, kuyilapho izinqubo zemishini zihilela ukuhlakazeka nokugaya amabhethri ukuze ahlukanise izinto.

Imishini yokugaywa kabusha kwebhethri ye-lithium ibalulekile ekwehliseni umthelela wemvelo wokulahlwa kwebhethri nokulondoloza izinsiza ngokuthola izinsimbi ezibalulekile nezinto ezingasetshenziswa kabusha kumabhethri amasha noma kweminye imikhiqizo.

Ngaphezu kwezinzuzo zokongiwa kwemvelo nezinsiza, okokusebenza kabusha kwebhethri ye-lithium nakho kunezinzuzo zezomnotho.Ukuthola izinsimbi ezibalulekile nezinto ezisetshenziswayo kumabhethri asetshenzisiwe kunganciphisa izindleko zokukhiqiza amabhethri amasha, kuphinde kudale imizila yemali emisha yezinkampani ezibandakanyekayo enqubweni yokugaywa kabusha.

Ngaphezu kwalokho, ukwanda kwesidingo sezimoto zikagesi nezinye izinto zikagesi kuqhuba isidingo semboni esebenza kahle futhi esimeme yokugaywa kabusha kwamabhethri.Imishini yokugaywa kabusha kwebhethri ye-lithium ingasiza ukuhlangabezana nalesi sidingo ngokuhlinzeka ngendlela ethembekile nengabizi kakhulu yokuthola izinto ezibalulekile kumabhethri asetshenzisiwe.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugaywa kabusha kwebhethri ye-lithium kuseyimboni entsha uma kuqhathaniswa, futhi kunezinselelo okufanele uzinqobe mayelana nokuthuthukisa izinqubo zokugaywa kabusha ezisebenza kahle nezingabizi.Ukwengeza, ukuphatha kahle kanye nokulahlwa kwemfucuza yebhethri kubalulekile ukuze kugwenywe izingozi zemvelo nempilo.Ngakho-ke, kufanele kube nemithethonqubo efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukuphathwa kahle nokugaywa kabusha kwamabhethri e-lithium.