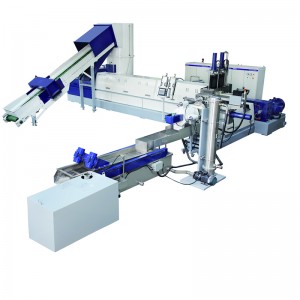

Umshini wePlastiki Wokwenza kabusha udoti wefilimu ye-HDPE (ifilimu yesihlukanisi sebhethri ye-lithium)

Umshini wePlastiki Wokwenza kabusha udoti wefilimu ye-HDPE(ifilimu yesihlukanisi sebhethri ye-lithium)

Enqubweni yokukhiqiza isihlukanisi sebhethri ye-lithium nge-hydrometallurgy, kuzokhiqizwa inani elikhulu lezinto ezinqamulelayo (i-HDPE ultra-high molecular weight polyethylene).Le offcut(ifilimu yemfucuza ye-HDPE) ingagaywa kabusha ukuze isetshenziswe amapayipi, amapulasitiki ashintshiwe neminye imikhiqizo, enenani eliphezulu lokusetshenziswa.Ngesikhathi sokucutshungulwa kwale mikhiqizo, izinto ezikhiyiwe zizofakwa i-granulated ngaphambi kokusetshenziswa.Ngenxa yezinga eliphansi lokuncibilika lokugeleza kwe-UHMWPE noma i-UHMWPE, ukucubungula i-extrusion kunzima.I-PURUI inikeza indlela entsha yokuwohloka nokubuyiselwa kwemfucuza ye-polyethylene ephezulu kakhulu noma ephezulu kakhulu.Le ndlela inenqubo yokutakula elula, engasetshenziswa ukwehlisa isithunzi nokubuyisela i-polyethylene yesisindo samangqamuzana ephezulu kakhulu noma ephezulu ngendlela ehambisana nemvelo futhi ephumelelayo, okwenza imfucumfucu ye-polyethylene ngemva kokuwohloka ibe nokucutshungulwa kahle, ngaleyo ndlela ibone ukugaywa kabusha kwe-offcut. izinto zokwakha, ezinezinzuzo ezinhle zezomnotho.

Ulayini wokugaywa kabusha kwepulasitikiukuphula uchungechunge lwemolekyuli ye-polyethylene ephezulu kakhulu noma ephezulu kakhulu (UHMWPE) ngokuchoboza ifilimu (okungukuthi into esele equkethe i-polyethylene ephezulu kakhulu noma ephezulu kakhulu) bese uyiphakela i-extruder, futhi bese incibilikisa i-extruding ngaphansi kwezinga lokushisa elithile eliphakeme kanye nesenzo sokugunda isikulufu se-extruder, ukuze iketango lamangqamuzana e-UHMWPE noma i-polyethylene yesisindo samangqamuzana ephezulu kakhulu iphuke, ngaleyo ndlela ibe nokushelela okuphezulu kwezinga lokushisa nokucutshungulwa kalula, ukuqaphela ukutholwa kwensiza nokusetshenziswa kabusha. , kanye nokulondoloza izindleko zebhizinisi.

Izinyathelo zokugaywa kabusha kwepulasitiki:

(1) Gcoba: ukuchoboza ifilimu yemfucuza ye-HDPE ibe ngu-30mm ngomshini we-plastic crusher bese uphakela i-agglomerator ngesithuthi sebhande.

(2) Extrusion: extruding ngaphansi kwezinga lokushisa phakathi 160 ukuze 250 ℃, isivinini rotary njengoba 60-150rpm, L/D njengoba 30-50

(3) I-granulation/i-pelletizing: izinto ezincibilikayo nezikhiphayo zisikwa ngohlelo lokusika olungaphansi kwamanzi, ama-pellets okugcina njengo-2mm.

4

Ividiyo:

Izici:

Inqubo elula, izindleko eziphansi

I-PUUI'sumugqa we-granulationingakwazi ukubona ukugaywa kabusha kwezinto ezilahlwayo ze-polyethylene esezingeni eliphezulu kakhulu noma ephezulu kakhulu, okungukuthi, i-offcut, futhi iyisebenzisele ukucubungula amapayipi awela phansi nomfula, amapulasitiki ashintshiwe neminye imikhiqizo, ukuxazulula inkinga yokucubungula ubunzima ngezindlela zendabuko;Ukwengeza, ayikho ingxenye yamakhemikhali eyengezwe ngesikhathi sokugaywa kabusha/i-granulating, engeke ibangele ukungcoliswa kwesibili futhi izoba nobungane ngokwemvelo;Kuzuzwa ukugaywa kabusha kwezinsiza ezilahlwayo, konga izindleko futhi kunezinzuzo ezinkulu kwezomnotho.

Imishini ye-granulation kanye nendlela yokutakula eklanywe i-PURUI ilulaza ngempumelelo futhi ilulame i-UHMWPE.I-material ingancibilika futhi igeleze, futhi ingaphinda yenziwe i-granulated.Impahla inamandla aphezulu emishini.

Umshini wepulasitiki ogaywe kabusha kanye ne-granulating uhlobo lwempahla esetshenziswa ukugaywa kabusha imfucumfucu yepulasitiki ibe yizinhlayiyana noma ama-pellets angasetshenziswa kabusha ekwenzeni imikhiqizo emisha yepulasitiki.Umshini ngokuvamile usebenza ngokuhlikihla noma ukugaya udoti wepulasitiki ube izingcezu ezincane, bese uyancibilikisa futhi uwukhiphe ngedayidi ukuze wakhe ama-pellets noma ama-granules.

Kunezinhlobo ezahlukene zemishini yokugaywa kabusha yepulasitiki kanye ne-granulating etholakalayo, okuhlanganisa isikulufu esisodwa kanye nezikhiphi eziphuma ngamawele.Eminye imishini ihlanganisa izici ezengeziwe ezifana nezikrini zokususa ukungcola emfucumfucwini yepulasitiki noma izinhlelo zokupholisa ukuze kuqinisekiswe ukuthi ama-pellets aqina ngendlela efanele.Umshini wokuwasha amabhodlela we-PET, umugqa wokugeza izikhwama we-PP

Imishini yokugaywa kabusha kwepulasitiki kanye ne-granulating ivamise ukusetshenziswa ezimbonini ezikhiqiza udoti omkhulu wepulasitiki, njengokupakisha, ezezimoto, nezokwakha.Ngokwenza kabusha imfucumfucu yepulasitiki, le mishini isiza ukunciphisa umthelela wemvelo wokulahlwa kwepulasitiki futhi ilondoloze izinsiza ngokusebenzisa kabusha izinto ebezingalahlwa.

Imishini yokugaywa kabusha kwebhethri ye-lithium iwuhlobo lwempahla esetshenziswa ukuphinda igaywe futhi ithole izinto ezibalulekile kumabhethri e-lithium-ion, avame ukusetshenziswa kumishini kagesi efana nama-smartphone, amalaptop, nezimoto zikagesi.Okokusebenza ngokuvamile kusebenza ngokwephula amabhethri ezingxenyeni zawo, njenge-cathode nezinto ze-anode, isixazululo se-electrolyte, namafoil ensimbi, bese ehlukanisa futhi ehlanza lezi zinto ukuze ziphinde zisetshenziswe.

Kunezinhlobo ezahlukene zemishini yokuvuselela ibhethri ye-lithium etholakalayo, okuhlanganisa izinqubo ze-pyrometallurgical, izinqubo ze-hydrometallurgical, nezinqubo zemishini.Izinqubo ze-Pyrometallurgical zibandakanya ukucutshungulwa kwezinga lokushisa eliphezulu kwamabhethri ukuze kubuyiselwe izinsimbi ezifana nethusi, i-nickel, ne-cobalt.Izinqubo ze-Hydrometallurgical zisebenzisa izixazululo zamakhemikhali ukuze zihlakaze izingxenye zebhethri futhi zibuyisele izinsimbi, kuyilapho izinqubo zemishini zihilela ukuhlakazeka nokugaya amabhethri ukuze ahlukanise izinto.

Imishini yokugaywa kabusha kwebhethri ye-lithium ibalulekile ekwehliseni umthelela wemvelo wokulahlwa kwebhethri nokulondoloza izinsiza ngokuthola izinsimbi ezibalulekile nezinto ezingasetshenziswa kabusha kumabhethri amasha noma kweminye imikhiqizo.

Ngaphezu kwezinzuzo zokongiwa kwemvelo nezinsiza, okokusebenza kabusha kwebhethri le-lithium nakho kunezinzuzo zezomnotho.Ukuthola izinsimbi ezibalulekile nezinto ezisetshenziswayo kumabhethri asetshenzisiwe kunganciphisa izindleko zokukhiqiza amabhethri amasha, kuphinde kudale imizila yemali emisha yezinkampani ezibandakanyekayo enqubweni yokugaywa kabusha.

Ngaphezu kwalokho, ukwanda kwesidingo sezimoto zikagesi nezinye izinto zikagesi kuqhuba isidingo semboni esebenza kahle futhi esimeme yokugaywa kabusha kwamabhethri.Imishini yokugaywa kabusha kwebhethri ye-lithium ingasiza ukuhlangabezana nalesi sidingo ngokuhlinzeka ngendlela ethembekile nengabizi kakhulu yokuthola izinto ezibalulekile kumabhethri asetshenzisiwe.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugaywa kabusha kwebhethri ye-lithium kuseyimboni entsha uma kuqhathaniswa, futhi kunezinselelo okufanele uzinqobe mayelana nokuthuthukisa izinqubo zokugaywa kabusha ezisebenza kahle nezingabizi.Ukwengeza, ukuphatha kahle kanye nokulahlwa kwemfucuza yebhethri kubalulekile ukuze kugwenywe izingozi zemvelo nempilo.Ngakho-ke, kufanele kube nemithethonqubo efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukuphathwa kahle nokugaywa kabusha kwamabhethri e-lithium.