umshini wokugaya kabusha wepulasitiki wefilimu yezolimo

Okuhlangenwe nakho

Ngamandla amahle wekhono lokukhiqiza, ubuchwepheshe be-PURUI senziwe imishini emihle kakhulu yokugaywa kabusha kwepulasitiki kanye nesixazululo kuzo zonke izinhlobo zokugaywa kabusha kwefilimu yemfucuza, ukugaywa kabusha kwebhethri le-acid eholayo, ukugaywa kabusha kwebhodlela le-PET.asilethi izixazululo zokugaywa kabusha kumakhasimende hhayi kuzo zonke izinhlobo zamapulasitiki kuphela, kodwa nakumoshi webhethri kagesi kanye nebhethri le-lead acid.

Ake siqale ngefilimu enzima kakhulu njengesihloko esingakhuluma ngaso :

Uma kunezintambo zokuwasha amafilimu ezinikezelwe ekugayweni kabusha kwefilimu yezolimo, amaphuzu abalulekile enqubo yokuwasha kabusha yilawa:

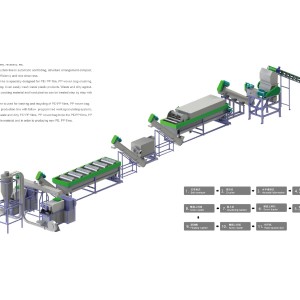

Ibhande elihambisa ibhande +trommel + crusher/shredder+horizontalIwasha i-friction+isivinini esikhuluIwasha i-friction+ ithangi elintantayo+spiral loader+squeezer+silo

(1) Khipha inhlabathi/udaka kunoma yimuphi umshini wokuwasha ngokushesha ngangokunokwenzeka ukuze ugweme noma iluphi udaka olunqwabelana phansi ethangini, ukuze udaka/udaka olusindayo, oluqinile nolunamathelayo lungakwazi ukuthatha indawo ngaphakathi. Igumbi lokuwasha, futhi linikeze ukusebenza okulindelekile kokuwasha.

(2) Umshini wokugeza iFriction ungasusa kalula inhlabathi eningi nodaka ngokusebenzisa i-centrifuge yesivinini esikhulu kanye nokushayisana okunamapaddles ku-shaft.Kodwa qaphela ukuthi kungenzeka kuminyene egumbini leFriction Washer ngomklamo ongafanele.

(3) Zama ukugcina ifilimu eligoqiwe nelisontekile livulekile-flat.Wonke umuntu uyazi ukuthi ukuthatha uhlamvu lwemali ephaketheni lakho jeans ngesikhathi ilondolo kunzima kakhulu.Kunzima njengokugeza ifilimu eligoqiwe futhi lisontekile.Ifilimu eyisicaba kalula ingavumela ukungcola kuphume phakathi nenqubo yokuwasha, ukuze i-extruder yakho ingaphakelwa ukungcola, noma ikhulise isikhathi sokuphila sokushintsha isikrini.

Imininingwane Yezobuchwepheshe

| Ukusetshenziswa kwamandla Ngokuqhathanisa (kw/Hr) | ||||

|

| 500 Kg/Ihora | 1.0 Ton/Ihora | 1.5 Ton/Ihora | 2.0 Ton/Ihora |

| Efilimini Yasekhaya | 190-230 | 220-250 | 240~265 | 300-330 |

| Ifilimu ye-AG | 295~330 | 350 ~ 420 | 375-450 | 420~475 |

| Ifilimu yangemva kwabathengi | 260~330 | 300 ~ 420 | 330-450 | 380~475 |

| Ukusetshenziswa kwamanzi Ngokuqhathanisa | |||

| Uhlobo lwefilimu / Umthombo | Endlini | AG | I-post-Consumer |

| M3 / Hr | 3~5 | 15-20 | 8~12 |

Izindleko Zokugqoka Nokugcina

I-PURUI Tech ibilokhu ibeka umzamo omkhulu ekwehliseni ukuguga kwezingxenye zemishini.Ukwehliswa kwezindleko ezihambisana nokulungisa kungasebenza ngezingcezu ezishintshayo, ukwakheka kwezindlu okuhlala isikhathi eside, kanye nomklamo ophelele wommese kanye nokusika kwawo.Ngaphezu kwalokho, ngenxa yokugezwa okwengeziwe kwangaphambili kwe-PURUI Tech ibhalansisa kahle izindleko zokutshalwa kwezimali kokuqala kanye nezindleko zokuguga nokugcinwa kwemishini engaphansi kakhulu esenzweni esilimazayo sezinto ezingcoliswe kakhulu.

Ukomisa amamojula athile

Ukomisa kufanele kucutshungulwe ngokucophelela lapho welapha amafilimu ezolimo amancane kakhulu, lapho lesi sinyathelo senqubo yokuvuselela kabusha sibucayi kakhulu.Amamojula athile aklanywe yi-PURUI Tech ukuze abhekane nale nkinga futhi enze inqubo yokomisa ngaphandle kokulimaza ifilimu ekhiqiziwe.

Umshini wepulasitiki ogaywe kabusha kanye ne-granulating uhlobo lwempahla esetshenziswa ukugaywa kabusha imfucumfucu yepulasitiki ibe yizinhlayiyana noma ama-pellets angasetshenziswa kabusha ekwenzeni imikhiqizo emisha yepulasitiki.Umshini ngokuvamile usebenza ngokuhlikihla noma ukugaya udoti wepulasitiki ube izingcezu ezincane, bese uyancibilikisa futhi uwukhiphe ngedayidi ukuze wakhe ama-pellets noma ama-granules.

Kunezinhlobo ezahlukene zemishini yokugaywa kabusha yepulasitiki kanye ne-granulating etholakalayo, okuhlanganisa isikulufu esisodwa kanye nezikhiphi eziphuma ngamawele.Eminye imishini ihlanganisa izici ezengeziwe ezifana nezikrini zokususa ukungcola emfucumfucwini yepulasitiki noma izinhlelo zokupholisa ukuze kuqinisekiswe ukuthi ama-pellets aqina ngendlela efanele.Umshini wokuwasha amabhodlela we-PET, umugqa wokugeza izikhwama we-PP

Imishini yokugaywa kabusha kwepulasitiki kanye ne-granulating ivamise ukusetshenziswa ezimbonini ezikhiqiza udoti omkhulu wepulasitiki, njengokupakisha, ezezimoto, nezokwakha.Ngokwenza kabusha imfucumfucu yepulasitiki, le mishini isiza ukunciphisa umthelela wemvelo wokulahlwa kwepulasitiki futhi ilondoloze izinsiza ngokusebenzisa kabusha izinto ebezingalahlwa.

Imishini yokugaywa kabusha kwebhethri ye-lithium iwuhlobo lwempahla esetshenziswa ukuphinda igaywe futhi ithole izinto ezibalulekile kumabhethri e-lithium-ion, avame ukusetshenziswa kumishini kagesi efana nama-smartphone, amalaptop, nezimoto zikagesi.Okokusebenza ngokuvamile kusebenza ngokwephula amabhethri ezingxenyeni zawo, njenge-cathode nezinto ze-anode, isixazululo se-electrolyte, namafoil ensimbi, bese ehlukanisa futhi ehlanza lezi zinto ukuze ziphinde zisetshenziswe.

Kunezinhlobo ezahlukene zemishini yokuvuselela ibhethri ye-lithium etholakalayo, okuhlanganisa izinqubo ze-pyrometallurgical, izinqubo ze-hydrometallurgical, nezinqubo zemishini.Izinqubo ze-Pyrometallurgical zibandakanya ukucutshungulwa kwezinga lokushisa eliphezulu kwamabhethri ukuze kubuyiselwe izinsimbi ezifana nethusi, i-nickel, ne-cobalt.Izinqubo ze-Hydrometallurgical zisebenzisa izixazululo zamakhemikhali ukuze zihlakaze izingxenye zebhethri futhi zibuyisele izinsimbi, kuyilapho izinqubo zemishini zihilela ukuhlakazeka nokugaya amabhethri ukuze ahlukanise izinto.

Imishini yokugaywa kabusha kwebhethri ye-lithium ibalulekile ekwehliseni umthelela wemvelo wokulahlwa kwebhethri nokulondoloza izinsiza ngokuthola izinsimbi ezibalulekile nezinto ezingasetshenziswa kabusha kumabhethri amasha noma kweminye imikhiqizo.

Ngaphezu kwezinzuzo zokongiwa kwemvelo nezinsiza, okokusebenza kabusha kwebhethri le-lithium nakho kunezinzuzo zezomnotho.Ukuthola izinsimbi ezibalulekile nezinto ezisetshenziswayo kumabhethri asetshenzisiwe kunganciphisa izindleko zokukhiqiza amabhethri amasha, kuphinde kudale imizila yemali emisha yezinkampani ezibandakanyekayo enqubweni yokugaywa kabusha.

Ngaphezu kwalokho, ukwanda kwesidingo sezimoto zikagesi nezinye izinto zikagesi kuqhuba isidingo semboni esebenza kahle futhi esimeme yokugaywa kabusha kwamabhethri.Imishini yokugaywa kabusha kwebhethri ye-lithium ingasiza ukuhlangabezana nalesi sidingo ngokuhlinzeka ngendlela ethembekile nengabizi kakhulu yokuthola izinto ezibalulekile kumabhethri asetshenzisiwe.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugaywa kabusha kwebhethri ye-lithium kuseyimboni entsha uma kuqhathaniswa, futhi kunezinselelo okufanele uzinqobe mayelana nokuthuthukisa izinqubo zokugaywa kabusha ezisebenza kahle nezingabizi.Ukwengeza, ukuphatha kahle kanye nokulahlwa kwemfucuza yebhethri kubalulekile ukuze kugwenywe izingozi zemvelo nempilo.Ngakho-ke, kufanele kube nemithethonqubo efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukuphathwa kahle nokugaywa kabusha kwamabhethri e-lithium.