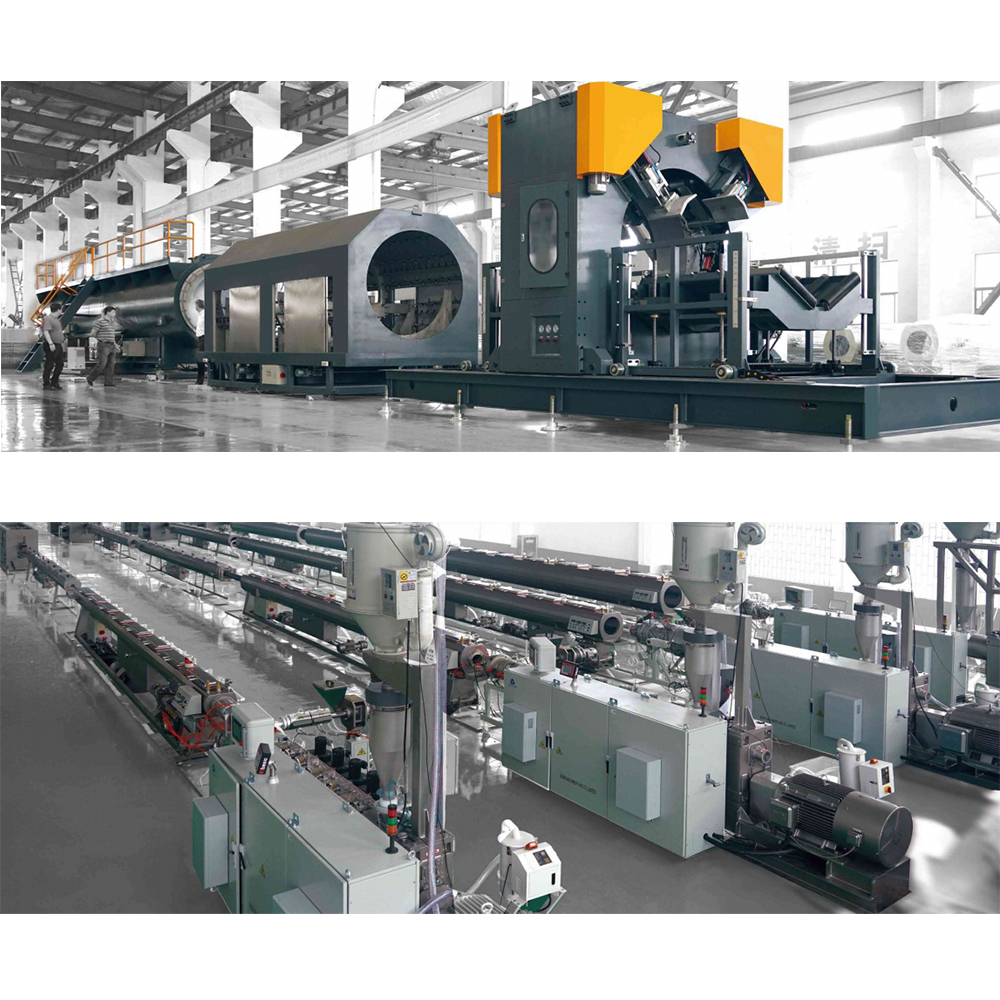

Umshini wokwenza amapayipi we-PVC

Ividiyo yomkhiqizo:

I-1.PPR ingasetshenziselwa ukushisa phansi, ukushisa okuphakathi kwendawo yokuhlala kanye nezimboni, ukuthutha kwezimboni (uketshezi lwamakhemikhali namagesi), ukuthuthwa kwamanzi okuphuza, izicelo ezikhethekile, ukuthuthwa kwamanzi ashisayo nabandayo.

Izinzuzo:

- Isikulufu se-extruder samukela i-L/D=38, ikhanda elixube kabili, isakhiwo esihlukanisiwe, senza ipulasitiki yezinto ezincibilikayo ngo-100% ngaphambi kokungena ekhanda lokuthinta.Vula i-spiral groove ekugcineni kwesiphakeli ukuze kwenyuswe isivuno ngo-30%

- Ikhanda lesikhunta lamukela ukwakheka kwe-spiral ngaphandle kwe-hysteresis phenomenon, engathuthukisa kakhulu ikhwalithi yezinto zamapayipi.I-sleeve engaguquki iyi-disc design ekhethekile, isiqinisekiso sepayipi ye-extrusion ephezulu

- Ibhokisi le-vacuum eliphindwe kabili liwukulawula okuzimele ngokuphelele futhi lisebenza ngendlela elula njengomugqa owodwa

- I-double tractor iyisilawuli esizimele ngokuphelele, esilungele ukusebenza njengomugqa owodwa, nedivayisi yomkhawulo wethrekhi ephezulu, engaqinisekisa ukuzungeza kwepayipi.

- I-double cutter i-chip-free cut enokulawula okuzimele ngokuphelele futhi kulula ukuyisebenzisa.

Ipharamitha eyinhloko:

| Imodeli | 60/38 | 75/38 | 90/38 | 120/38 | |

| Isicelo | Impahla eluhlaza | Umthamo omkhulu | |||

| Ukuhlinzekwa kwamanzi negesi | PE | 500 | 650 | 1100 | 1350 |

| I-Antistatic coating | I-PR-RT | 400 | 600 | 1000 | 1200 |

| Ukufakwa kwamapayipi | I-PPR | 350 | 520 | 800 | 1100 |

| Indle kanye Nendle | PP | 350 | 520 | 800 | 1000 |

2.PVC ipayipi

Isicelo:ipayipi lamanzi anomfutho, isistimu yamapayipi endle, isistimu yamapayipi okukhipha amanzi, izinto zikagesi kanye nepayipi lobunjiniyela bezokuxhumana

Imingcele yezobuchwepheshe eyinhloko

| Ububanzi bepayipi | 16-40 amapayipi amabili | 16-63 amapayipi amabili | 50-160 | 75-250 | 110-315 | 160-450 | 315-630 |

| Amawele angama-Conical crew extruder | SJZ51/105 | SJZ65/132 | SJZ65/132 | SJZ65/132 | SJZ80/1156 | SJZ80/156 | SJZ92/188 |

| Injini enkulu(kW) | 18.5AC | 37AC | 37AC | 37AC | 55AC | 55AC | 110AC |

| Umthamo omkhulu | 100-120 | 280-350 | 280-350 | 280-350 | 400-550 | 400-550 | 700-800 |

PE umshini wokwenza amapayipi 1

PE umshini wokwenza ipayipi 2

Umshini wokwenza amapayipi we-PVC

Umshini wepulasitiki ogaywe kabusha kanye ne-granulating uhlobo lwempahla esetshenziswa ukugaywa kabusha imfucumfucu yepulasitiki ibe yizinhlayiyana noma ama-pellets angasetshenziswa kabusha ekwenzeni imikhiqizo emisha yepulasitiki.Umshini ngokuvamile usebenza ngokuhlikihla noma ukugaya udoti wepulasitiki ube izingcezu ezincane, bese uyancibilikisa futhi uwukhiphe ngedayidi ukuze wakhe ama-pellets noma ama-granules.

Kunezinhlobo ezahlukene zemishini yokugaywa kabusha yepulasitiki kanye ne-granulating etholakalayo, okuhlanganisa isikulufu esisodwa kanye nezikhiphi eziphuma ngamawele.Eminye imishini ihlanganisa izici ezengeziwe ezifana nezikrini zokususa ukungcola emfucumfucwini yepulasitiki noma izinhlelo zokupholisa ukuze kuqinisekiswe ukuthi ama-pellets aqina ngendlela efanele.Umshini wokuwasha amabhodlela we-PET, umugqa wokugeza izikhwama we-PP

Imishini yokugaywa kabusha kwepulasitiki kanye ne-granulating ivamise ukusetshenziswa ezimbonini ezikhiqiza udoti omkhulu wepulasitiki, njengokupakisha, ezezimoto, nezokwakha.Ngokwenza kabusha imfucumfucu yepulasitiki, le mishini isiza ukunciphisa umthelela wemvelo wokulahlwa kwepulasitiki futhi ilondoloze izinsiza ngokusebenzisa kabusha izinto ebezingalahlwa.

Imishini yokugaywa kabusha kwebhethri ye-lithium iwuhlobo lwempahla esetshenziswa ukuphinda igaywe futhi ithole izinto ezibalulekile kumabhethri e-lithium-ion, avame ukusetshenziswa kumishini kagesi efana nama-smartphone, amalaptop, nezimoto zikagesi.Okokusebenza ngokuvamile kusebenza ngokwephula amabhethri ezingxenyeni zawo, njenge-cathode nezinto ze-anode, isixazululo se-electrolyte, namafoil ensimbi, bese ehlukanisa futhi ehlanza lezi zinto ukuze ziphinde zisetshenziswe.

Kunezinhlobo ezahlukene zemishini yokuvuselela ibhethri ye-lithium etholakalayo, okuhlanganisa izinqubo ze-pyrometallurgical, izinqubo ze-hydrometallurgical, nezinqubo zemishini.Izinqubo ze-Pyrometallurgical zibandakanya ukucutshungulwa kwezinga lokushisa eliphezulu kwamabhethri ukuze kubuyiselwe izinsimbi ezifana nethusi, i-nickel, ne-cobalt.Izinqubo ze-Hydrometallurgical zisebenzisa izixazululo zamakhemikhali ukuze zihlakaze izingxenye zebhethri futhi zibuyisele izinsimbi, kuyilapho izinqubo zemishini zihilela ukuhlakazeka nokugaya amabhethri ukuze ahlukanise izinto.

Imishini yokugaywa kabusha kwebhethri ye-lithium ibalulekile ekwehliseni umthelela wemvelo wokulahlwa kwebhethri nokulondoloza izinsiza ngokuthola izinsimbi ezibalulekile nezinto ezingasetshenziswa kabusha kumabhethri amasha noma kweminye imikhiqizo.

Ngaphezu kwezinzuzo zokongiwa kwemvelo nezinsiza, okokusebenza kabusha kwebhethri ye-lithium nakho kunezinzuzo zezomnotho.Ukuthola izinsimbi ezibalulekile nezinto ezisetshenziswayo kumabhethri asetshenzisiwe kunganciphisa izindleko zokukhiqiza amabhethri amasha, kuphinde kudale imizila yemali emisha yezinkampani ezibandakanyekayo enqubweni yokugaywa kabusha.

Ngaphezu kwalokho, ukwanda kwesidingo sezimoto zikagesi nezinye izinto zikagesi kuqhuba isidingo semboni esebenza kahle futhi esimeme yokugaywa kabusha kwamabhethri.Imishini yokugaywa kabusha kwebhethri ye-lithium ingasiza ukuhlangabezana nalesi sidingo ngokuhlinzeka ngendlela ethembekile nengabizi kakhulu yokuthola izinto ezibalulekile kumabhethri asetshenzisiwe.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugaywa kabusha kwebhethri ye-lithium kuseyimboni entsha uma kuqhathaniswa, futhi kunezinselelo okufanele uzinqobe mayelana nokuthuthukisa izinqubo zokugaywa kabusha ezisebenza kahle nezingabizi.Ukwengeza, ukuphatha kahle kanye nokulahlwa kwemfucuza yebhethri kubalulekile ukuze kugwenywe izingozi zemvelo nempilo.Ngakho-ke, kufanele kube nemithethonqubo efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ukuphathwa kahle nokugaywa kabusha kwamabhethri e-lithium.

I-FAQ yomugqa wepayipi we-PVC

Sicela uphendule imibuzo engezansi ukuze unikeze ukunikeza

1.Pukusebenza ipe

□ Ipayipi le-UPVC □ Ipayipi le-SPVC □ Ipayipi le-CPVC □ Okunye

2.Uhlelo lokusebenza:

Imikhiqizo yokugcina izosetshenziselwa:

□ Amanzi □ Ipayipi lamanzi noma indle □ Ikhebula □ Okunye

3.Ubukhulu.Iphesenti le-Caco3 (PHR)

□ Ngaphansi kuka-10 PHR □ 20-50PHR □ 50-100PHR □ Ngaphezu kuka-100PHR

4.Isakhiwo sesendlalelo

□ I-Monolayer

□ Izendlalelo ezimbili

□ Izendlalelo ezintathu

Sicela usize ukugcwalisa lelipayipi elingezansi:

| Isendlalelo | Okubalulekile | Isilinganiso | Qaphela |

| A | % | ||

| B | % | ||

| C | % |

5.Pipe ukubekezelela ukujiya

| Ipayipi Dia. | Ukujiya kokuma | Ukubekezelelana | Qaphela |

6.Okukhiphayo

□ Isisindo se-Extrusion: ____KGH * _____Amahora okusebenza ngosuku * ______Izinsuku zokusebenza ngonyaka

□ Isivinini sokukhipha: ____m/min

7.Ububanzi Bebhizinisi

| Inkomba | I-BEIER | Umthengi |

| Inqolobane | × | 1. Ubude*Ububanzi*Ubude: ____M*__M*___MPizikhundla ze-Pillar, ihlinzeka ngomdwebo we-CAD ku-BEIER 2. Iphansi eliphansi 3. Ukuphakama kwendawo: □ kufika ku-1000m(NN) ▽ ngaphezu kuka-1000m(NN), okungukuthi ………………..m(NN) |

| Ukugeleza kwamanzi | × | 1. Ishaneli yamanzi angaphansi komhlaba noma amapayipi e-PVC namaphampu? |

| I-Folk lift | × | 1. umthamo wokulayisha 3.5-5Ton |

| Ukunikezwa kukagesi | Ikhabethe likagesi | 1. Ingabe unayo i-transformer enamandla eyanele ukulayisha zonke izinjini namahhovisi amayunithi?2.Ikhebula/izintambo ukusuka ku-transformer kuya kukhabethe likagesi 3. Ikhebula/izintambo ezisuka kukhabhinethi kagesi ziye kumotho ngayinye 4. Amandla kagesi: Shayela ukunikezwa kwekhabhinethi: 3 Isigaba _____V ____Hz Ukunikezwa kwekhabhinethi yokulawula: ______V _____Hz Ukushintshashintsha kwe-voltage: □ kufika kubukhulu ± 10% ○ kufika kubukhulu ± 15% ▽ ngaphezu kuka-± 15%, |

8. Isimo Sengqalasizinda

Isimo sezulu Izinga lokushisa lendawoubuningi.umswakama ohlobene

| □ isilinganiso | kufika ku-35 ℃ | 70% |

| ▽ yomile/efudumele | kuze kufike ku-40 ℃ | 40% |

| ▽ yomile/kuyashisa | ngaphezulu kokungu-40 ℃, okungukuthi ………………….. ℃ | 40% |

| ▽ kunomswakama/ukufudumala | kuze kufike ku-40 ℃ | 90% |

| ▽ kunomswakama/kuyashisa | ngaphezulu kokungu-40 ℃, okungukuthi ………………….. ℃ | 90% |

I-FAQ yomugqa wepayipi we-HDPE

Sicela uphendule imibuzo engezansi ukuze unikeze ukunikeza

1.I-Raw Material

□ UBorouge □ Sabic □ ESinopec □ Abanye

2.Imigqa yemigqa enemibala

□ umugqa owodwa □ imigqa emibili □ imigqa emine □ imigqa eyisithupha □ imigqa eyisishiyagalombili

3.Isakhiwo sesendlalelo

□ I-Monolayer

□ Izendlalelo ezimbili

□ Izendlalelo ezintathu

□ Izendlalelo ezine

Sicela usize ukugcwalisa lelipayipi elingezansi:

| Isendlalelo | Okubalulekile | Isilinganiso | Qaphela |

| A | % | ||

| B | % | ||

| C | % | ||

| D | % |

4.Pipe ukubekezelela ukujiya

| Ipayipi Dia. | Ukujiya kokuma | Ukubekezelelana | Qaphela |

5.Okukhiphayo

□ Isisindo se-Extrusion: ____KGH * _____Amahora okusebenza ngosuku * ______Izinsuku zokusebenza ngonyaka

□ Isivinini sokukhipha: ____m/min

6.Isicelo:

Imikhiqizo yokugcina izosetshenziselwa:

□ amanzi □ ipayipi lamanzi noma indle □ Ipayipi legesi □ Ipayipi lokunisela

7.Ububanzi Bebhizinisi

| Inkomba | I-PURUI | Umthengi |

| Inqolobane | × | 1. Ubude*Ububanzi*Ubude: ____M*__M*___MPizikhundla ze-Pillar, ihlinzeka ngomdwebo we-CAD ku-BEIER 2. Iphansi eliphansi 3. Ukuphakama kwendawo: □ kufika ku-1000m(NN) ▽ ngaphezu kuka-1000m(NN), okungukuthi ………………..m(NN) |

| Ukugeleza kwamanzi | × | 1. Ishaneli yamanzi angaphansi komhlaba noma amapayipi e-PVC namaphampu? |

| I-Folk lift | × | 1. umthamo wokulayisha 3.5-5Ton |

| Ukunikezwa kukagesi | Ikhabethe likagesi | 1. Ingabe unayo i-transformer enamandla eyanele ukulayisha zonke izinjini namahhovisi amayunithi?2.Ikhebula/izintambo ukusuka ku-transformer kuya kukhabethe likagesi 3. Ikhebula/izintambo ezisuka kukhabhinethi kagesi ziye kumotho ngayinye 4. Amandla kagesi: Shayela ukunikezwa kwekhabhinethi: 3 Isigaba _____V ____Hz Ukunikezwa kwekhabhinethi yokulawula: ______V _____Hz Ukushintshashintsha kwe-voltage: □ kufika kubukhulu ± 10% ○ kufika kubukhulu ± 15% ▽ ngaphezu kuka-± 15%, |

8. Isimo Sengqalasizinda

Isimo sezulu Izinga lokushisa lendawoubuningi.umswakama ohlobene

| □ isilinganiso | kufika ku-35 ℃ | 70% |

| ▽ yomile/efudumele | kuze kufike ku-40 ℃ | 40% |

| ▽ yomile/kuyashisa | ngaphezulu kokungu-40 ℃, okungukuthi ………………….. ℃ | 40% |

| ▽ kunomswakama/ukufudumala | kuze kufike ku-40 ℃ | 90% |

| ▽ kunomswakama/kuyashisa | ngaphezulu kokungu-40 ℃, okungukuthi ………………….. ℃ | 90% |